Ancillary Products

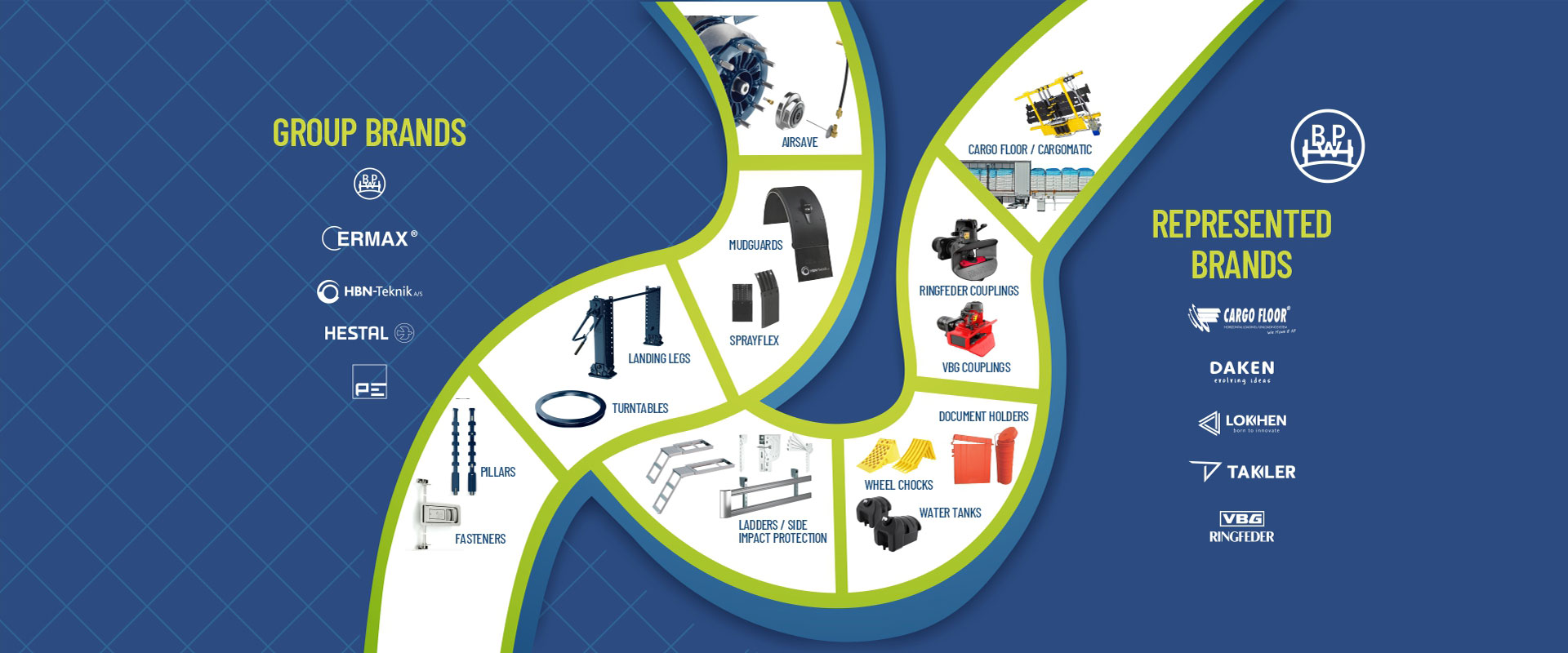

BPW Group Brands

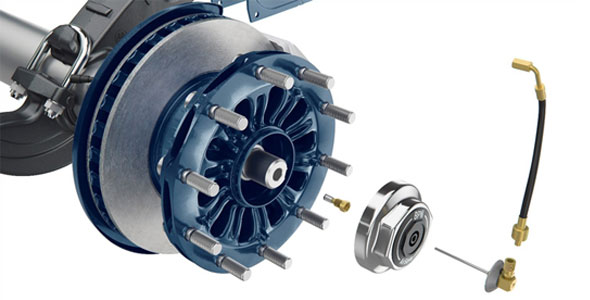

AirSave

Maximum cost-effectiveness and greater safety thanks to optimal tyre pressure. BPW’s AirSave allows you to continuously track and control your tyre pressure while driving.

The tyre pressure is constantly monitored and automatically adjusted to the desired level via a control box with booster.

Should the pressure deviate considerably from the norm, for example in the event of tyre damage, a warning light informs the driver to this effect so that they can promptly drive to a service station instead of having to stop on the side of the motorway. This significantly reduces the risk of accidents, prevents down times, saves fuel by maintaining optimal pressure at all times, and reduces CO2 emissions.

Better for the environment

The system cuts CO2 emissions and litter from burst tyres debris and blow-outs. Even the slightest pressure loss increases fuel consumption and therefore also the emissions of the vehicles enormously. Even a ten percent deviation in tyre pressure from the prescribed value increases fuel consumption by more than 250 litres over an annual distance of 120,000 kilometres. That is 655 kilograms of CO2, which could be saved. by using AirSave!!!

AirSave - Benefits

- Factory assembled – one source of supply: BPW!

- Robust and reliable thanks to the hubcap adapter: 2 year guarantee

- Service friendly – 3 years maintenance free

- Reduced downtimes

- Cost savings on tyres and fuel

Landing Gear

BPW Trailer Landing Gear stock is available in Johannesburg, Durban and Cape Town, minimising delivery cost and keeping the already keen pricing most competitive.

With BPW landing gears you are in a good position in all cases.

Your advantages at a glance:

Robust

Just the right thing for usage in heavy jobs with a trailer, thanks to the reinforced shaft for the absorption of lateral forces and the continuous screw-on plate for optimum strength. And all with built-in safety: BPW landing gears meet AAR* requirements.

Comfortable

The long, continuously perforated screw-on plate for different fixing positions ensures an easy, flexible installation. Low crank forces facilitate day-to-day tasks.

Economical

Advantages that pay off: BPW landing leg is particularly light – and therefore the first choice, if every kilo of vehicle load makes a difference. BPW landing gear is maintenance-free for three years due to the long-term greasing with BPW ECO Li 91. In addition, it impresses with the lowest level of wear and is optimally protected from corrosion through high-quality coatings.

* Association of American Railroads

BPW Landing Gear Technical Data / Installation and Operating Instructions

Mudguards and Antispray

HBN mudwings are well known in the industry for its superior quality with ISTOFLEX based on virgin material and a recycled version called GREENFLEX.

Both types have been developed for tough environments and rough handling, which is why we never compromise on quality.

Antispray

SPRAYFLEX® is a water suppression solution that increases traffic safety for other road users driving behind or passing a commercial vehicle. The antispray is designed and produced with a special impact resistant material that ensures that it maintains constant and rigid in all weather conditions. It fulfills the EU-directive of achieving a wind deflection below 100mm and absorbs more than 70% of the water spray by leading it back to the ground. Due to the patented design it also avoids ice and dirt being collected during transport which easily damages the mudwing because of the extra weight or damages other vehicles when released from the antispray. SPRAYFLEX is approved in the EU according to directive no.91-226-001. The directive dictates that min. 70% of the water must be led to the ground.

HBN-Teknik Mudwings & Antispray Specifications

Pillars, Locks and Fasteners

The HESTAL product range is a high quality, proven and tested product being extensively used in Europe. The product range includes:

Drop-side trailer fasteners, Curtain Sider Pillars, as well as pneumatic and / or cantilever roof lift systems. The pillars can accommodate a double deck option for the curtain sider trailers.

Additional products in this range of products are rear doors, hinges and locks for Reefer Trailers, including a coded entry electronic locking mechanism. All these products are TUV Certificated.

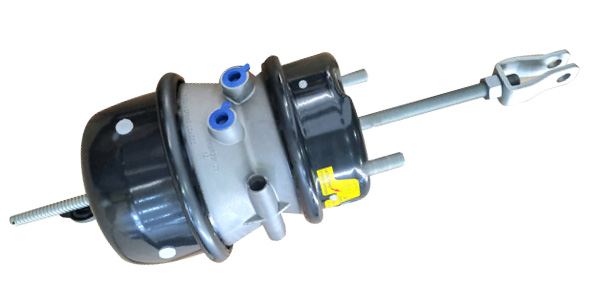

Brake Booster

In a brake system, it is of the utmost importance to achieve an optimum interplay between the individual components.

The power plant for your brake system. Brake cylinders from BPW.

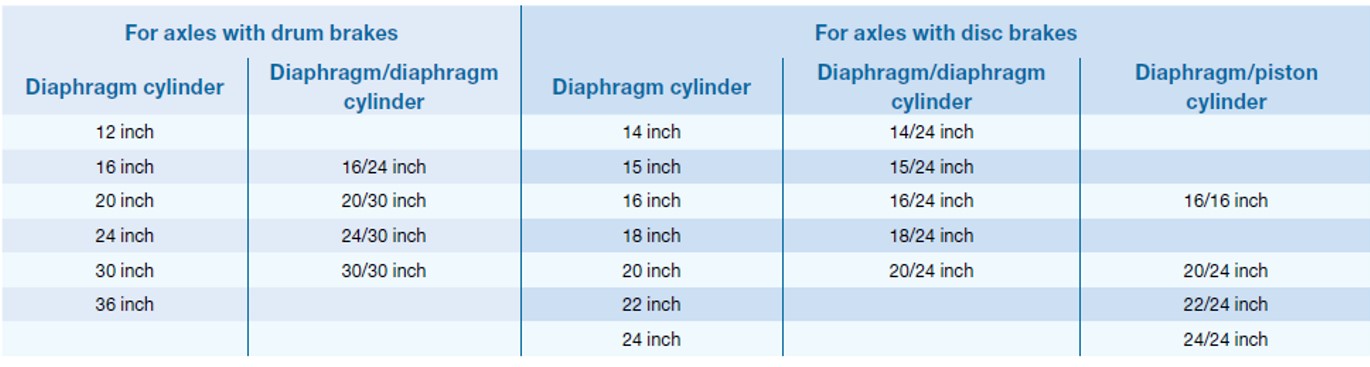

The brake cylinders have a decisive role to play in this, because they have to provide a perfectly modulated force transfer within the brake system. BPW develops and produces its own brake cylinders for drum and disc brakes – further proof of our extensive expertise when it comes to brakes. As a system supplier, our product range includes diaphragm and spring-type cylinders.

BPW Brake Cylinders – Features and Benefits

- Sustained high quality assured by testing and continuous quality checks (FMEA, dimension test, release pressure test, functional test on the vehicle, vibration test, dirt test, dynamic strength test, hot and cold test (80 °, -40 °), force BPW Brake Cylinder output check)

- Improved sealing using innovative flanging technique

- Optimum corrosion protection for the housing components by means of various high-quality coating procedures

- Optimum corrosion protection for the springs by means of double coating

- Inch and metric connections available

- Easy to install because of extended compressed air connection (standard in spring-type cylinders for disc brakes)

- In drum brakes, there is no need for an external return spring between the slack adjuster and air cylinder bracket (precondition: mounting on BPW axles, round hole yoke end and lever length 100 mm)

- New ECE certificates and test reports are available from the BPW website

Delivery variants of BPW Brake Cylinders

|

|

|

|

|

Diaphragm Cylinders |

Diaphragm-diaphragm (M-M) Cylinders |

Diaphragm-piston (M-K) Cylinders |

| They act as a service brake and are characterised by their compact external dimensions and low weight. | They act both as a service brake as well as an auxiliary and parking brake. They are lighter than the diaphragm-piston cylinder. |

They have the same function as a diaphragm/diaphragm cylinder. Their greater spring-type accumulator force means they are suited above all for vehicles with higher axle loads and limited installation space. |

LED Lights and Harnesses

The ERMAX product range offers LED lights and harnesses for trailers. The cable and plugs are ADR approved.

These lights are of multiple type, i.e. 3 in 1 or single lights (Indicator, Stop Light and Rear Light) (Reverse Light) (Number plate Light) (Working Light). Truck & Trailer rear light clusters, sealed and units that can be opened and individual sections be replaced are also available. The harnesses and junction boxes can be custom made to plug & play for any vehicle configuration. All these products are TUV Certificated.

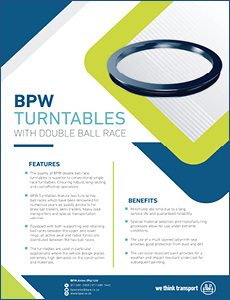

TWO ARE BETTER THAN ONE.

BPW turntables with double-row ball race.

BPW turntables outshine conventional single-row systems thanks to

their high-quality double-row ball race, which guarantees optimum

distribution of the axial and radial forces that are produced. This system has been proven over years of successful operation, and the advantages in its design are evident in daily use in truck trailers, semi-trailers, heavy-duty transporters and special vehicles. BPW turntables are used in particular applications where the vehicle design places extremely high demands on the construction and materials.

BPW Turntables Technical Data / Downloads

Installation and Maintenance Instruction

Ancillary Products

BPW Represented Brands

Moving Floors

The CARGO FLOOR automatic loading and unloading system can be used for automatic horizontal loading and unloading of various types of bulk materials & pallets and is used in trucks, trailers & factories.

With more than 30 years experience, excellent quality and an extremely high level of service Cargo Floor is now recognised in the entire industry as a world-renowned market leader! Cargo Floor manufactures its products in Coevorden, The Netherlands, under the ISO 9001-2008 quality label (certified by Lloyds).

Before delivery, the functionality, geometry and seals of the loading and unloading systems they manufacture are thoroughly tested. This guarantees easy integration wherever you are in the world and ensures that all Cargo Floor sliding floor loading and unloading systems they deliver work properly. Cargo Floor systems are modular, making it easy to replace their components.

Regular Checks & Preventative Maintenance

- Hydraulic Pump Requirements (PTO) – minimum 110 litres / minimum & maximum pressure on relief valve – 250 bar

- Hydraulic Tank Capacity – minimum 150 litres

- Recommended Hydraulic Oil – ISO 32 between: {-15ºC and 30ºC} / ISO 46 between: {-15ºC and 40ºC}

To ensure that your Cargo Floor system operates reliably and has a long life, it is important that you regularly perform careful checks on the following aspects:

- Change the hydraulic oil every 2 years, or more frequently if required

- Oil tank – clean out trap in lid from any foreign particles

- Check the coupling nuts and couplings (Ball or Pin type – not interchangeable)

- Hydraulic Return Pressure filter – check condition, replace yearly

- NB!! - Replace the Cargo Floor filter element every year, or more often if needed

- Check the connection between the aluminium profiles and the Cargo Floor system from receipt of the new trailer or after 10 loads / unloads and thereafter monthly. Are they still fixed? – replace screws if necessary (FINGER TEST - You do this by placing your finger half on the screw and half on the floor profile when the floor is operating)

- Check guide blocks on piston rods for wear

- Check the seal between the fixated profiles and the moving floor profiles. If a margin exists in between then adjust the fixated floor profiles, in order for the sealing to be optimal and leakage via the side walls is prevented

CF500 SLC Cargo Bulkmover

The Bulkmover is the smart solution for transport of bulk products.

Mainly for loose product

Because the floor profiles of the Cargo Bulkmover are wider than the standard 21 floor profile execution this concept is not suitable for the loading and unloading of pallets and paper reels with the help of the floor movement of the Cargo Floor system. Off course pallets eg. can be loaded - and unloaded - by driving a hand pallet truck or fork lift truck over the floor. More than 20 years of experience with the wide floor profiles, mainly in stationary factory applications, has proven that the 15 floor profile version of the Cargo Floor system is extremely suitable for the efficient unloading of most common loose products in large volumes.

Weight reduction

In order to reduce weight in a safe and reliable way Cargo Floor has developed an alternative floor: an execution which has 15 floor profiles instead of the usual 21. The total moving floor surface is exactly equal to the the 21 moving floor profiles, because of which no adjustment of the side profile is needed.

|

|

Characteristics of the 15 floor profile Cargo Bulkmover concept:

- Weight advantage for the complete trailer; depending on the execution at least 60 kg. and can go up to 300 kg

- 30% less seams between the floor profiles; possible leakage and wear substantially decreases

- 30% less seal between the floor profiles. Also the seal is very well protected from the product transported

- 30% less mounting time for the sub floor construction, floor profiles and bearing

- Increased stability of the floor profiles because of the "cargo twister wide 40/25" bearing with very wide bearing surface and support on three spots

- Very large bearing surface, because of which less wear

- Less wear

- Larger bearing and sliding surface of the "cargo twister wide 40/25" (+7%)

- Bearing does not come into contact with the transported product (no extra wear) and is protected against spattering street dirt by the floor profile

- Floor width is identical to the standard 21 floor profile execution; no need to adjust the side profile

- All hydraulic components: cylinders, valves, are identical to the CF500 SL-C 21 floor profile system

- Suitable for the power speed execution: unloading in +/- 3 min. (ask about the requirements)

- Various floor profiles available, among which a special HD and ultimate XHDI version for the transport of all kinds of waste: glass, sand eg.

- Very clean discharge

- Suitable for all types of cargo floor drive units

- Extreme long durability

- Robust and very stable

- No maintenance required

- Absolutely lower cost of ownership

- 30% less work if a floor revision needs to be done and turning the floor is a lot easier

- Pallets, paper reels eg: only loading / unloading with the help of a fork lift truck or pallet wagon

Fork-lift truck

In principle all Cargo Floor floors can be driven on by a fork-lift truck; contact your body builder for information about the permitted weights!

|

|

CargoMatic

The CargoMatic transport system is the ultimate loading and unloading system (dock to trailer) for packaged/palletised products (not bulk products; see the Cargo Floor transport system for information on this) and extremely suitable for shuttle traffic/transport over short distances. A semitrailer with a length of 13,600 mm with a CargoMatic system can be loaded or unloaded within 90 seconds.

The CargoMatic transport system has a fully flat loading and unloading floor that operates as a conveyor belt. A semitrailer with a CargoMatic system can be loaded and unloaded very fast and simply; loading and unloading using a forklift truck is also a lot more efficient. The load is moved forwards and backwards completely automatically by the CargoMatic transport system and the forklift truck therefore does not have to be driven into the semitrailer anymore.

|

|

Document Holders, Wheel Chocks and Water Tanks

Based in Italy LOKHEN is a Leader in the production of accessories for trucks and trailers, continually generating innovation, pushed by the will of being famous for excellence.

Innovation is Lokhen's motto. They innovate to improve and to make their products even faster, practical and simple to use by professional users. Lokhen is a dynamic reality with a great background and a growing potential, a leader in the plastic sector of trucks & trailer.

Lokhen produces what the customer will require and according to what the future holds. Advanced technologies is the basis of their productive process, which translate R&D and Innovation tasks in a response to the market's needs, which have UNIQUE and HIGH-QUALITY STANDARDS.

BPW is the official distribution partner for Lokhen branded products.

Water Tanks

Document Holders

Wheel Chocks

Trailer Couplings, MechMatic and Redline

Manufacturing a wide range of trailer couplings and assorted towing eyes designed for heavy-duty applications. RINGFEDER and VBG high quality products clearly handle the challenging conditions of our continent.

VBG COUPLINGS - THE SMART GENERATION - Certified and approved couplings for all types of transport. VBG’s couplings are well-known for their high quality, high reliability, and long service life with low maintenance costs. They offer you peace of mind, year in and year out. The VBG coupling is digital and it has been given new safety functions based on sensor technology. In addition, VBG has improved the mechanics and made the coupling both smaller and lighter.

RINGFEDER COUPLINGS - THE NEW GENERATION - A new generation providing unparalleled reliability, product life and total cost of ownership. The new trailer couplings are more compact yet sturdier. Exposed parts are reinforced while service and maintenance have been made easier. In addition, there are new features for convenience, safety, and time-saving.

Together the VBG and Ringfeder brand accounts for a 50% market share globally in there category.

VBG Couplings

RINGFEDER Couplings

APPLICATIONS

VBG MECHMATIC - Automatic lubrication and cleaning

TIP: If you supplement with VBG MechMatic, lubrication and cleaning are performed completely automatically. This saves time and trouble for the driver and reduces service and maintenance costs.

- Keeps the coupling mechanism clean with regular air shocks and an injection of thin oil mist

- Suitable for all VBG yoke coupling and Ringfeder drawbar couplings

- Reduces servicing needs and conception of lubricant

- Assists with prolonging the service life of the coupling

- VBG MechOil last for approximately 3000 hours of operation

|

|

REDLINE – Operate with Air

Ringfeder AIR Operated coupling, is all that and much more. By using the existing air in the truck, you will open the coupling in no time, with no more unnecessary long stops trying to position your trailer to uncouple.

- By using the existing air in the truck, you will open the coupling in no time

- No more unnecessary long stops trying to position your trailer to uncouple

- Suitable for 40/50mm AM/AR couplings

- A conversion kit is available for 40/50mm A/B Type couplings

|

|

|

|

|

|

|

|

Toolboxes and Fire Extinguisher Boxes

DAKEN is a world leader in production and distribution of plastic accessories for commercial vehicles. In the field of plastic accessories, uniform thickness means higher quality.

Injection moulding process is the key of DAKEN success. Unlike rotational moulding process, it guarantees precise finishing with uniform thickness and higher production speed. The excellent quality of materials and technologies, and the high efficiency of the production process represent only some of the competitive advantages of DAKEN injection moulding toolboxes and fire extinguishers.

DAKEN toolboxes, made of first quality raw materials, are the flagship of DAKEN products. Not only can DAKEN toolboxes make or save you money, their 1250 mm toolbox is up to 100+ kg lighter than a similarly sized steel toolbox. DAKEN toolboxes are TÜV certified and have been designed with a reinforced structure to last in time.

DAKEN fire extinguisher cabinets for commercial vehicles are reliable and safe and guarantee maximum efficiency in emergency situations. All DAKEN fire extinguisher cabinets are made of Polypropylene guaranteeing full resistance even in the weakest points.

BPW is the official distribution partner for DAKEN branded products. We also supply Impact Buffers.

WELVET Toolboxes

First choice raw materials, solid structure and the reliability guaranteed by certifications are only some of the competitive advantages of this line. Welvet toolboxes are the perfect mix of high quality, solidity and a unique and elegant design.

|

|

|

WELVET TOOLBOX 400mm |

WELVET TOOLBOX 600mm |

|

|

|

WELVET TOOLBOX 800mm |

WELVET TOOLBOX 1000mm |

ARKA Toolboxes

Arka is our new line of toolboxes. Daken's new challenge is to combine in one product a high quality structure and the advantages of stack ability. As all our toolboxes, even Arka line is made by injection moulding system, which, together with the reinforced structure, guarantees resistance and durability. Arka toolboxes are homologated as Lateral Protection System.

|

|

|

AKRA TOOLBOX 600mm |

AKRA TOOLBOX 800mm |

|

|

|

AKRA TOOLBOX 1000mm |

AKRA TOOLBOX 1250mm |

Fire Extinguishers

Side Impact Protection, Brackets and Ladders

TAKLER safety devices and accessories are user-friendly and able to fulfill the stringent requirements of the commercial automotive field. Takler operates on the basis of international standards of safety and quality guaranteed by certifications.

The side impact protection device is Takler’s top product: they offer a full range of profiles: aluminum, plastic, magnelis® to satisfy each and every customer requirement. The universal usage of its accessories and components allows having multiple customized configurations perfectly complying with homologation rules valid in Europe and in Extra-European countries.

Takler brackets, both fixed and adjustable, can conform to any given chassis fixing solution in order to have the sideguard correctly installed. Their adjustable brackets guarantee the opening of the lateral protection device, without bolts or pins being moved. Patented opening system keeps the whole sideguard open at 90° and 130°.

Takler think ladders not as a mere accessory for the vehicle but as an essential working tool. Takler's vision and aim on the ladder throughout the whole process of design and production; is to offer the market a tool making the truck more comfortable, safe and resistant.

BPW is the official distribution partner for TAKLER branded products.